Technical parameters of CNC horizontal lathe:

| project | unit | CK6153 | CK6165 | CK6180 | CK61100 | ||||||

| machine range | Large turning diameter on the bed | ㎜ | Ф530 | Ф650 | Ф800 | Ф1000 | |||||

| Large turning diameter on the slide | ㎜ | Ф300 | Ф320 | Ф470 | Ф600 | ||||||

| Large support length between two tips | ㎜ | 100 | 1500 | 1500 | 3000 | 1500 | 3000 | 5000 | 3000 | 5000 | |

| Large processing length | ㎜ | 820 | 1320 | 1350 | 2850 | 1350 | 2850 | 4850 | 2850 | 4850 | |

| main shaft | Range of spindle speed | t/min | 30-150 90-450 315-1600 | 8-40 40-200 200-800 | 8-40 40-200 200-800 | 4-40 6-150 50-450 | |||||

| spindle bore | ㎜ | Ф90 | Ф105 | Ф105 | Ф140 | ||||||

| Bar capacity diameter | ㎜ | Ф80 | Ф100 | Ф100 | Ф160 | ||||||

| Chuck specifications | ㎜ | 250 | Ф320 | Ф320 | Ф500 | ||||||

| Taper of spindle bore | 100/1:20 | 120/1:20 | 120/1:20 | 150/1:20 | |||||||

| Spindle end type | A2-8 | D11 | D11 | A2-15 | |||||||

| Spindle motor power | kw | 7.5 | 15 | 15 | 22 | ||||||

| tool carrier | Tool holder and tool position | station | 4/6 | 4/6/8 | 4/6/8 | 4/6/8 | |||||

| Knife bar and square size | ㎜ | 25×25 | 32×32 | 32×32 | 32×32 | ||||||

| Boring tool bar diameter | ㎜ | Ф32 | Ф40 | Ф40 | Ф40 | ||||||

| trip | X-axis stroke | ㎜ | 300 | 320 | 320 | 650 | |||||

| Z-axis travel | ㎜ | 1000 | 1500 | 1500 | 3000 | 1500 | 3000 | 5000 | 3000 | 5000 | |

| feed | X/Z axis fast moving speed | m/min | 4/6 | 4/5 | 4/5 | 4/5 | |||||

| feed rate | ㎜/min | 4000 | 4000 | 4000 | 4000 | ||||||

| X/Z-axis motor torque | Nm | 6/10 | 15/22 | 15/22 | 15/30 | ||||||

| tailstock | Tail socket diameter | ㎜ | Ф75 | Ф100 | Ф100 | Ф160 | |||||

| Taper of tailstock quill | MT5 | MT6 | MT6 | Ф80 1:20 | |||||||

| Tailstock sleeve stroke | ㎜ | 120 | 250 | 250 | 300 | ||||||

| rail | Width of bed guide rail | ㎜ | 440 | 600 | 600 | 800 | |||||

| Bed guide rail type | Hard track | Hard track | Hard track | Hard track | |||||||

| accuracy | X/Z axis positioning accuracy | ㎜ | 0.015/0.022 | 0.015/0.022 | 0.015/0.022 | 0.016/0.025 | |||||

| X/Z axis repeated positioning accuracy | ㎜ | 0.012/0.016 | 0.012/0.016 | 0.012/0.016 | 0.016/0.018 | ||||||

| other | Machine weight | kg | 2500 | 2700 | 4100 | 5100 | 5600 | 6600 | 8100 | 12500 | 14500 |

| cover an area | ㎜ | 2570×1350 | 3070×1350 | 3940×2360 | 5540×2360 | 3940×2360 | 5540×2360 | 7540×2360 | 6500×3000 | 8500×3000 | |

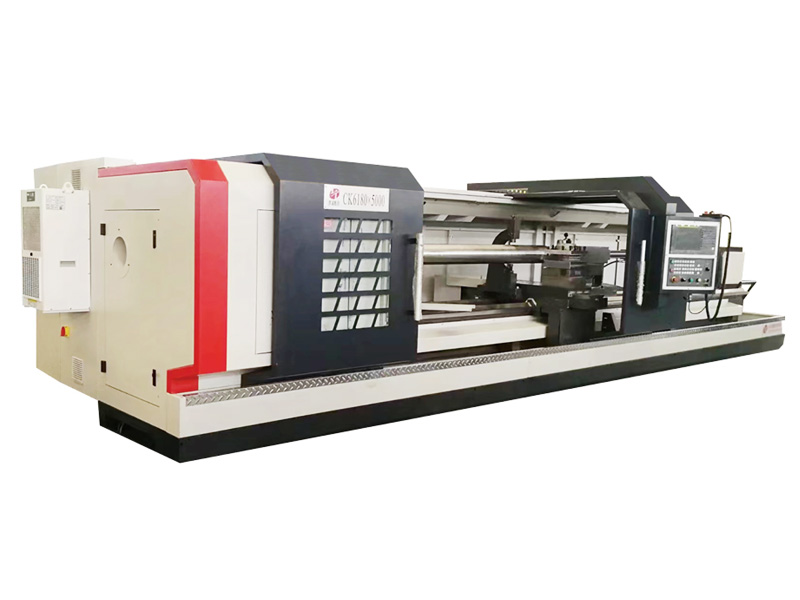

CK6153/CK6165/CK6180/CK61100

Heavy CNC horizontal lathe

★ Integrated casting structure for bed body and bed legs, ultra wide heavy-duty guide rail

★ High strength resin Sand casting casting parts, guide rail surface ultra audio quenching

★ C3 level ball screw

★ Automatic intermittent oil lubrication system

★ Four station electric dao rack

★ Semi protective sheet metal protection

★ CNC system: optional imported and domestic