| project | unit | Model | |||||

| CK61200 | CK61250 | CK61320 | CK61360 | CK61420 | CK61500 | ||

| Large turning diameter | ㎜ | 2000 | 2500 | 3200 | 3600 | 4200 | 5000 |

| Large machining diameter through tool holder | ㎜ | 1600 | 2000 | 2500 | 3000 | 3500 | 4000 |

| Number of guide rails | n | 4 | 2+2 | 2+2 | 2+2 | 2+2 | 2+2 |

| Bed width | ㎜ | 1600/2100 | 1300/1400 | 1300/1400 | 1500/1500 | 1500/1500 | 1800/2000 |

| Large load-bearing capacity between two tips | t | 25-80 | 50-125 | 50-125 | 80-125 | 80-125 | 80-125 |

| Large cutting force | kn | 63 | 140 | 140 | 140 | 140 | 140 |

| Spindle front bearing diameter | ㎜ | 300-500 | 380-710 | 380-710 | 500-710 | 500-710 | 500-710 |

| Tail socket diameter | ㎜ | 300-500 | 360-630 | 360-630 | 500-630 | 500-630 | 500-630 |

| High spindle torque | kNm | 39-95 | 81-160 | 81-160 | 95-160 | 95-160 | 95-160 |

| High spindle speed | r/Min | 125 | 100 | 90 | 75 | 63 | 63 |

| Main motor power | kw | 125 | 81-166 | 81-166 | 99-225 | 99-225 | 99-225 |

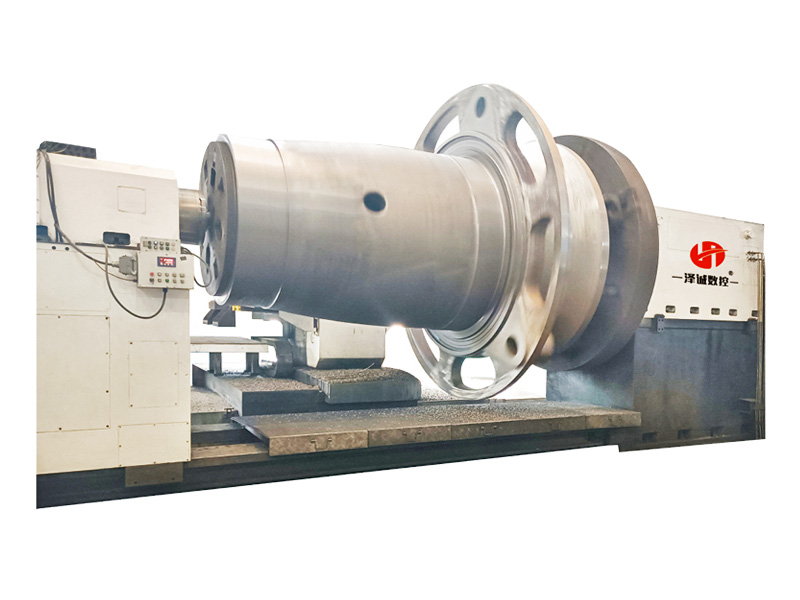

Introduction to CNC heavy-duty horizontal lathe products:

The CK61 series CNC heavy-duty horizontal lathe has the characteristics of strong load-bearing capacity, high efficiency, high accuracy, reasonable structure, wide applicability, and easy operation. In addition to the basic performance of heavy-duty lathes, it can also perform automatic machining of conical surfaces, curved surfaces, step shafts, grooves, and threads; Equipped with different special accessories, it can be used for grinding, milling, machining of interior holes, etc. It is widely used in metallurgy, energy, transportation, and other heavy machine manufacturing industries, for processing such as wind turbine rotors, hydropower rotors, rolling mills, large oil pressure machine piston rods, steam turbine rotors, generator spindles, and machine spindles.