Control lathe is a high-precision and efficient automated machine tool equipped with multi station turrets or power turrets, which has a wide range of processing performance. It can process complex workpieces such as linear cylinders, oblique cylinders, arcs, and various threads, grooves, worms, etc. It has various compensation functions such as linear interpolation and arc interpolation, and can play a good role in batch production. It combines the characteristics of a universal lathe, a high-precision lathe, and a specialized ordinary lathe with high processing efficiency, and can well meet the requirements of enterprises to improve product quality, reduce production costs, and improve economic benefits. So CNC lathes are a type of machine tool widely used and covered in China. In the processing of CNC lathes, product quality and labor productivity are largely constrained by cutting tools. Although the cutting principle of their turning tools is basically the same as that of ordinary lathes, how to fully utilize the functions and advantages of CNC lathes, ensure machining accuracy, improve labor efficiency, and control machining costs based on the actual situation of the processed parts is the key.

1. Part analysis

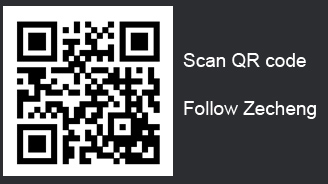

The product requested by the customer to be processed is the wheel axle cover (see Figure 1), with two parts A and B already processed, and the inner hole rough machined to 90mm. The accuracy requirements of the product are not very high, and the shape is not too complex, but the batch size is large (8000 pieces per month). The material is gray cast iron HT200, with a rough diameter of 150mm and a length of 40mm. Technical requirement: Undeclared chamfer is 1 × 45 °, unmarked tolerance shall be processed according to level m in GB/T 1804-2000. The equipment is equipped with 6 GSK980T economical CNC lathes from Guangzhou Machine Tool Factory.

2. Problems in the original processing

The original production and processing used two welded alloy turning tools, which were used for rough turning, precision turning of the outer circle, end face, and inner hole processing. Welded alloy knives are prone to wear and tear, and are generally suitable for rough turning. The material used for wheel axle cover parts is cast iron, with a hard surface, and the knives are prone to wear and tear. The precision of blade grinding cannot be guaranteed, and it takes up a long time, which can greatly reduce the surface accuracy of the processed wheel axle cover parts. Changing the tool requires changing the entire tool, which increases the cost of the tool. The GSK98T tool holder cannot automatically load and unload tools according to processing requirements, and requires manual tool replacement. Due to uneven force on the positioning pin and other reasons, the thread is also prone to damage, and using two knives cannot guarantee accuracy, which is time-consuming. During the machining process, it is necessary to frequently rotate the tool holder to change the tool, which leads to easy wear of the tool holder, deviation in positioning accuracy, and also prone to malfunctions (on average, one tool per 4 days). The maintenance personnel of the machine tool factory have repeatedly visited the site for maintenance, which cannot solve the problem, resulting in production stoppage and increased maintenance costs. Due to the increased auxiliary time required for tool re alignment, testing, and debugging after tool change, as well as the longer processing time for two tools, automatic tool change of the tool holder, and idle travel, the processing efficiency is greatly affected.

3. Basis for improving cutting tools

Through analyzing and studying the problems of tool structure, process design, programming and other aspects, it is considered that the original tool needs to be improved. The specific considerations are as follows.

(1) Select standardized tools and switch to machine clamp indexable turning tools. Because the wheel axle cover is mass-produced, CNC turning tools should use machine clamp indexable turning tools because: ① high accuracy. Ensure high repeated positioning accuracy of the blade, facilitate positioning, and ensure the accuracy of the blade tip position. This way, the blade wear does not require replacing the entire blade, but only replacing the blade High reliability. A structurally reliable turning tool that adopts a composite clamping structure to adapt to rapid movement and displacement of the tool holder, as well as to prevent loosening during the entire automatic cutting process. Quickly replace different forms of cutting components, complete various cutting processes, and improve production efficiency Low tool cost. Due to mass production and replaceable blades, although the machine clamp blade is more expensive, the cost of the tool will not increase, but will decrease and be more durable.

(2) Optimize the tool structure. Use as few cutting tools as possible to machine the upper part or most of the surface to be machined, in order to reduce clamping errors and improve the mutual position accuracy of the machined surfaces. If the two knives for machining the wheel axle cover can be combined into a "one knife" handle for machining, then ① the tool holder will not rotate. Only 'one knife' is being processed, so there is no need to rotate the tool holder. The tool holder will not affect accuracy due to wear and tear, and will not cause production stoppage, maintenance, and other issues Protect the positioning pins. The positioning of "one knife" only requires a set of positioning pins, and if standardized tools are used, only loosen and tighten the positioning screws of the tool tip when changing the tool, and do not need to loosen or tighten the positioning pins of the tool holder to install or remove the tool holder. The positioning pins of the tool holder will not be damaged.

(3) If standardized tool selection and optimized tool structure are combined, there will be no problem of long machine occupation time. Because: ① standardized machine clamp indexable cutting tools are selected, when one cutting edge on the blade is blunt, the installation, disassembly, and indexing of the blade are very convenient and fast, and new cutting edges can be used to continue processing without grinding, greatly improving the utilization rate of the tool holder. Just do a quick and simple tool setting, and make appropriate adjustments when programming By adopting an optimized tool structure scheme, the distance between the two tool tips must be closer than the original two tool tips, greatly reducing the time for tool replacement and idle operation. Combined with processing technology and programming, a shorter idle line and cutting feed path can be designed to effectively improve production efficiency and reduce tool wear.

4. Improved cutting tools

Through the above analysis and research, and based on existing understanding and processing conditions, I have solved the problems in the machining of wheel axle cover parts from the aspects of tool structure design, process processing, and programming. The specific methods are as follows.

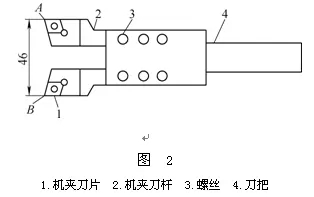

(1) Combine the two machined knives into one machine clamp knife (see Figure 2). The blade is heat treated and the blade tips A and B are fixed with screws, so that "one knife" can also complete the work of the original two knives, and loading and unloading "one knife" saves half the time compared to the original two knives.

(2) When using the improved tool for machining, there is no need to change the tool holder, which effectively solves the problems of faults and maintenance caused by frequent rotation of the tool holder for tool replacement.

(3) After the tool is worn, simply loosen the screw to rotate the non regrinding blade to an appropriate angle or replace it, and make simple modifications to the tool compensation stroke to continue machining, greatly improving efficiency.

5. Precautions during processing

(1) Fix the non regrinding blades A and B on the left and right sides with screws, ensuring that the two blade tips are on the same plane.

(2) When writing the program, it is necessary to set two sets of tool compensators (01, 02) with two independent tool points A and B as the tool tips. When converting the tool tips, the tool should be at a certain distance from the workpiece to prevent collision between the tool and the workpiece.

(3) The tool should be rotated once per shift to ensure the locking force of the tool holder.

6. Programming

The program and instructions written are shown in the attached table.

Program Content and Description

Program Description

O1212 Program Name

G00X100Z100 positioning to the starting point

T0101M3S200 calls for a set of tool compensation A # tool tips

G00X150Z0

Machining end face

G01X80F80

G00X150Z5 positioning to (150, 5)

G71U1R0.5 processing φ 145mm outer circle and chamfer

G71P1Q2U0W0F100

N1G00X143

G01Z0

X145Z-1

Z-16

G00X100Z100T0101 Return to the starting point to cancel a set of tool compensation

T0102M3S250 calls for the second set of tool compensation B # tool tip

G00X80Z5

G71U1R0.5 rough machining φ 112mm and φ 98mm inner hole and chamfer

G71P3Q4U-0.5W0F80

N3G00X114

G01Z0F50

X112Z-1

Z-11

X100

X98Z-11

N4Z-48

G70P3Q4 precision machining N3-N4 section content

G00X100Z100T0102 Return to the starting point to cancel the second set of tool compensation

M30 program ended

7. Conclusion

By improving the cutting tools and processing methods, the problem of batch processing on economical CNC lathes has been effectively solved, greatly reducing the downtime for repair, debugging time, automatic tool change, and idle travel time, reducing the labor intensity of operators, and significantly saving costs.

| Previous:Longmen Processing Center Technology Promotes Industrial Development | next:Longmen Processing Center Technology Promotes Industrial Development |